HP 6В мотор 48CPR энкодер 25D мм

- үнэ: 95,000 төг

HP 6V Motor with 48 CPR Encoder for 25D mm Metal Gearmotors (No Gearbox)

Pololu item #: 2269

This is the motor and encoder portion of our high-power (HP), 6V 25D mm metal gearmotors with 48 CPR encoders. It does not include a gearbox, but the pinion gear on the output shaft works with all of our 25D mm gearmotor gearboxes, so this can be used as a replacement motor or encoder for those gearboxes.

Key specs at 6 V: 10,000 RPM and 275 mA free-run, 5 oz-in (0.35 kg-cm) and 6.5 A stall.

Dimensions

| Size: | 24.2D x 43L mm |

|---|---|

| Weight: | 60 g |

General specifications

| Gear ratio: | 1:1 |

|---|---|

| No-load speed @ 6V: | 10000 rpm |

| No-load current @ 6V: | 275 mA |

| Stall current @ 6V: | 6500 mA |

| Stall torque @ 6V: | 5 oz·in |

| Lead length: | 8 in |

| Motor type: | 6.5A stall @ 6V (HP 6V) |

| Encoders?: | Y |

Overview

This motor with integrated 48 CPR (counts per revolution) quadrature encoder is intended as a replacement high-power (HP) 6 V motor with encoder for our 25D mm metal gearmotors. It is intended for use at 12 V, but in general, these kinds of motors can run at voltages above and below this nominal voltage. Lower voltages might not be practical, and higher voltages could start negatively affecting the life of the motor.

The output shaft has a non-removable pinion gear that works with all of our 25D mm gearmotor gearboxes. Note that we do not sell the 25D mm gearboxes separately, but if you have a gearmotor with a damaged motor or encoder (or if you want to effectively add an encoder to a version without an encoder), you can transfer the gearbox to this replacement motor.

The motor has a diameter of 24.2 mm (0.95 in) and a length of approximately 43 mm (1.7 in) from the top of the motor can to the bottom of the encoder. The top of the motor has two mounting holes threaded for M3 screws. These mounting holes are 17 mm apart and form a line with the motor shaft at the center. The mounting holes have a depth of approximately 6.5 mm.

Pinion gear specs

- – Metric with module m = 0.4

- – Number of teeth: 12

- – Face thickness: 2.5 mm

- – Pressure angle: 20°

- – Gear position: 4.5 mm from top of motor to top of gear

Gearmotor options

You will typically want to combine this motor with a gearbox to give it a more appropriate combination of torque and speed (without a gearbox, it offers very high speed with very low torque). The HP 6V versions of our 25D mm metal gearmotors consist of this motor combined with different gearboxes. We do not carry the gearboxes by themselves, so unless you are looking at this as a replacement motor for a compatible gearbox you already have, we strongly recommend you consider getting a preassembled gearmotor with the gear ratio that best suits your project requirements.

| Rated Voltage |

Motor Type | Stall Current @ Rated Voltage |

No-Load Speed @ Rated Voltage |

Approximate Stall Torque @ Rated Voltage |

With Encoder |

Without Encoder |

|---|---|---|---|---|---|---|

| 6 V | high-power (HP) |

6.5 A | 10,000 RPM | 5 oz-in | 1:1 HP 6V w/encoder | |

| 2150 RPM | 20 oz-in | 4.4:1 HP 6V w/encoder | 4.4:1 HP 6V | |||

| 990 RPM | 39 oz-in | 9.7:1 HP 6V w/encoder | 9.7:1 HP 6V | |||

| 460 RPM | 75 oz-in | 20.4:1 HP 6V w/encoder | 20.4:1 HP 6V | |||

| 280 RPM | 90 oz-in | 34:1 HP 6V w/encoder | 34:1 HP 6V | |||

| 200 RPM | 115 oz-in | 47:1 HP 6V w/encoder | 47:1 HP 6V | |||

| 130 RPM | 150 oz-in | 75:1 HP 6V w/encoder | 75:1 HP 6V | |||

| 97 RPM | 210 oz-in | 99:1 HP 6V w/encoder | 99:1 HP 6V | |||

| 56 RPM | 350 oz-in | 172:1 HP 6V w/encoder | 172:1 HP 6V | |||

| 6 V | low-power (LP) |

2.4 A | 6200 RPM | 2 oz-in | 1:1 LP 6V w/encoder | |

| 1300 RPM | 8 oz-in | 4.4:1 LP 6V w/encoder | 4.4:1 LP 6V | |||

| 590 RPM | 17 oz-in | 9.7:1 LP 6V w/encoder | 9.7:1 LP 6V | |||

| 290 RPM | 33 oz-in | 20.4:1 LP 6V w/encoder | 20.4:1 LP 6V | |||

| 170 RPM | 50 oz-in | 34:1 LP 6V w/encoder | 34:1 LP 6V | |||

| 120 RPM | 65 oz-in | 47:1 LP 6V w/encoder | 47:1 LP 6V | |||

| 78 RPM | 95 oz-in | 75:1 LP 6V w/encoder | 75:1 LP 6V | |||

| 58 RPM | 130 oz-in | 99:1 LP 6V w/encoder | 99:1 LP 6V | |||

| 34 RPM | 200 oz-in | 172:1 LP 6V w/encoder | 172:1 LP 6V | |||

| 25 RPM | 220 oz-in | 227:1 LP 6V w/encoder | 227:1 LP 6V | |||

| 15 RPM | 300 oz-in | 378:1 LP 6V w/encoder | 378:1 LP 6V | |||

| 11 RPM | 400 oz-in | 499:1 LP 6V w/encoder | 499:1 LP 6V | |||

| 12 V | high-power (HP) |

5.6 A | 10,200 RPM | 5.5 oz-in | 1:1 HP 12V w/encoder | |

| 2250 RPM | 23 oz-in | 4.4:1 HP 12V w/encoder | 4.4:1 HP 12V | |||

| 1030 RPM | 44 oz-in | 9.7:1 HP 12V w/encoder | 9.7:1 HP 12V | |||

| 500 RPM | 85 oz-in | 20.4:1 HP 12V w/encoder | 20.4:1 HP 12V | |||

| 290 RPM | 120 oz-in | 34:1 HP 12V w/encoder | 34:1 HP 12V | |||

| 210 RPM | 165 oz-in | 47:1 HP 12V w/encoder | 47:1 HP 12V | |||

| 130 RPM | 240 oz-in | 75:1 HP 12V w/encoder | 75:1 HP 12V | |||

| 100 RPM | 300 oz-in | 99:1 HP 12V w/encoder | 99:1 HP 12V | |||

| 12 V | medium-power (MP) |

2.1 A | 7800 RPM | 2.7 oz-in | 1:1 MP 12V w/encoder | |

| 1700 RPM | 11 oz-in | 4.4:1 MP 12V w/encoder | 4.4:1 MP 12V | |||

| 770 RPM | 22 oz-in | 9.7:1 MP 12V w/encoder | 9.7:1 MP 12V | |||

| 370 RPM | 42 oz-in | 20.4:1 MP 12V w/encoder | 20.4:1 MP 12V | |||

| 220 RPM | 63 oz-in | 34:1 MP 12V w/encoder | 34:1 MP 12V | |||

| 160 RPM | 85 oz-in | 47:1 MP 12V w/encoder | 47:1 MP 12V | |||

| 100 RPM | 125 oz-in | 75:1 MP 12V w/encoder | 75:1 MP 12V | |||

| 76 RPM | 165 oz-in | 99:1 MP 12V w/encoder | 99:1 MP 12V | |||

| 43 RPM | 250 oz-in | 172:1 MP 12V w/encoder | 172:1 MP 12V | |||

| 33 RPM | 320 oz-in | 227:1 MP 12V w/encoder | 227:1 MP 12V | |||

| 12 V | low-power (LP) |

1.1 A | 5600 RPM | 2 oz-in | 1:1 LP 12V w/encoder | |

| 1200 RPM | 8 oz-in | 4.4:1 LP 12V w/encoder | 4.4:1 LP 12V | |||

| 560 RPM | 15 oz-in | 9.7:1 LP 12V w/encoder | 9.7:1 LP 12V | |||

| 260 RPM | 29 oz-in | 20.4:1 LP 12V w/encoder | 20.4:1 LP 12V | |||

| 150 RPM | 43 oz-in | 34:1 LP 12V w/encoder | 34:1 LP 12V | |||

| 110 RPM | 60 oz-in | 47:1 LP 12V w/encoder | 47:1 LP 12V | |||

| 71 RPM | 85 oz-in | 75:1 LP 12V w/encoder | 75:1 LP 12V | |||

| 55 RPM | 115 oz-in | 99:1 LP 12V w/encoder | 99:1 LP 12V | |||

| 31 RPM | 180 oz-in | 172:1 LP 12V w/encoder | 172:1 LP 12V | |||

| 23 RPM | 240 oz-in | 227:1 LP 12V w/encoder | 227:1 LP 12V | |||

| 14 RPM | 320 oz-in | 378:1 LP 12V w/encoder | 378:1 LP 12V | |||

Note: Stalling or overloading gearmotors can greatly decrease their lifetimes and even result in immediate damage. For these gearboxes, the recommended upper limit for instantaneous torque is 200 oz-in (15 kg-cm); we strongly advise keeping applied loads well under this limit. Stalls can also result in rapid (potentially on the order of a second) thermal damage to the motor windings and brushes, especially for the versions that use high-power (HP) motors; a general recommendation for brushed DC motor operation is 25% or less of the stall current.

|

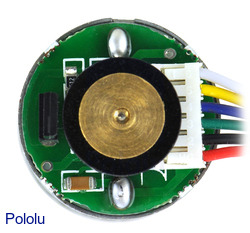

| 25D mm metal gearmotor with 48 CPR encoder: close-up view of encoder. |

|---|

|

Using the encoder

A two-channel Hall effect encoder is used to sense the rotation of a magnetic disk on a rear protrusion of the motor shaft. The quadrature encoder provides a resolution of 48 counts per revolution of the motor shaft when counting both edges of both channels. To compute the counts per revolution of the gearbox output, multiply the gear ratio by 48. The motor/encoder has six color-coded, 11″ (28 cm) leads terminated by a 1×6 female header with a 0.1″ pitch, as shown in the main product picture. This header works with standard 0.1″ male headers and our male jumper and precrimped wires. If this header is not convenient for your application, you can pull the crimped wires out of the header or cut the header off. The following table describes the wire functions:

| Color | Function |

|---|---|

| Red | motor power (connects to one motor terminal) |

| Black | motor power (connects to the other motor terminal) |

| Green | encoder GND |

| Blue | encoder Vcc (3.5 – 20 V) |

| Yellow | encoder A output |

| White | encoder B output |

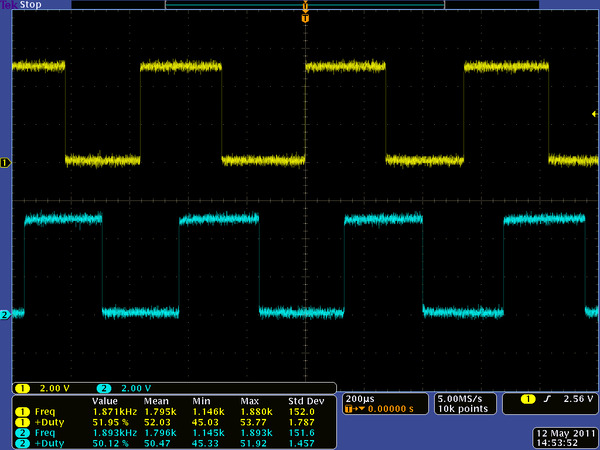

The Hall sensor requires an input voltage, Vcc, between 3.5 and 20 V and draws a maximum of 10 mA. The A and B outputs are square waves from 0 V to Vcc approximately 90° out of phase. The frequency of the transitions tells you the speed of the motor, and the order of the transitions tells you the direction. The following oscilloscope capture shows the A and B (yellow and white) encoder outputs using a motor voltage of 6 V and a Hall sensor Vcc of 5 V:

|

| Encoder A and B outputs for 25D mm HP 6V metal gearmotor with 48 CPR encoder (motor running at 6 V). |

|---|

By counting both the rising and falling edges of both the A and B outputs, it is possible to get 48 counts per revolution of the motor shaft. Using just a single edge of one channel results in 12 counts per revolution of the motor shaft, so the frequency of the A output in the above oscilloscope capture is 12 times the motor rotation frequency.

Санал болгох бараа

Үйлдвэрлэгч

МОТОР, ДУГУЙ

- Дугуй

- Туслах хэрэгсэл

- Явах эд анги

- DC мотор

- Серво мотор

- Алхамт мотор

Гал хамгаалагч

- Автомат гал хамгаалагч

- Термо гал хамгаалагч

- Радиал гал хамгаалагч

- Шилэн гал хамгаалагч

- 6х30мм

- 5х20мм

- 3.6x10мм

- Шаазан гал хамгаалагч

- Гал хамгаалагчийн үүр

Диод

- 7-н сегмент

- Гэрлэн диод

- Мостон диод

- Тогтворжуулагч диод

- Фото диод

- Шулуутгагч диод

- Шоттки диод

Кварц

Конденсатор

- Туйлгүй конденсатор

- Туйлтай конденсатор

- Хувьсах конденсатор

Микросхем

- ADC

- DAC

- Optocoupler

- RTC

- Serial eeprom

- Timer

- Аудио

- Видео

- Логик элемент

- Микроконтроллёр

- Үйлдлийн өсгүүр

Ороомог

Тиристор

- Диак

- Cемистор

- Тиристор

Транзистор

- IGBT транзистор

- Биполяр транзистор

- Оронт транзистор

Трансформатор

Эсэргүүцэл

- 0.25W

- 2W

- 5W

- 7W

- 10W

- Хувьсах эсэргүүцэл

Лавлах утас: 77107805, 99198321

Хаяг : Улаанбаатар хот, Чингэлтэй дүүрэг, Компьютер ланд, 3-н давхар, 12 тоот

“ЧИП ЭЛЕКТРОНИКС” ХХК

© Copyright – 2025 www.chip.mn